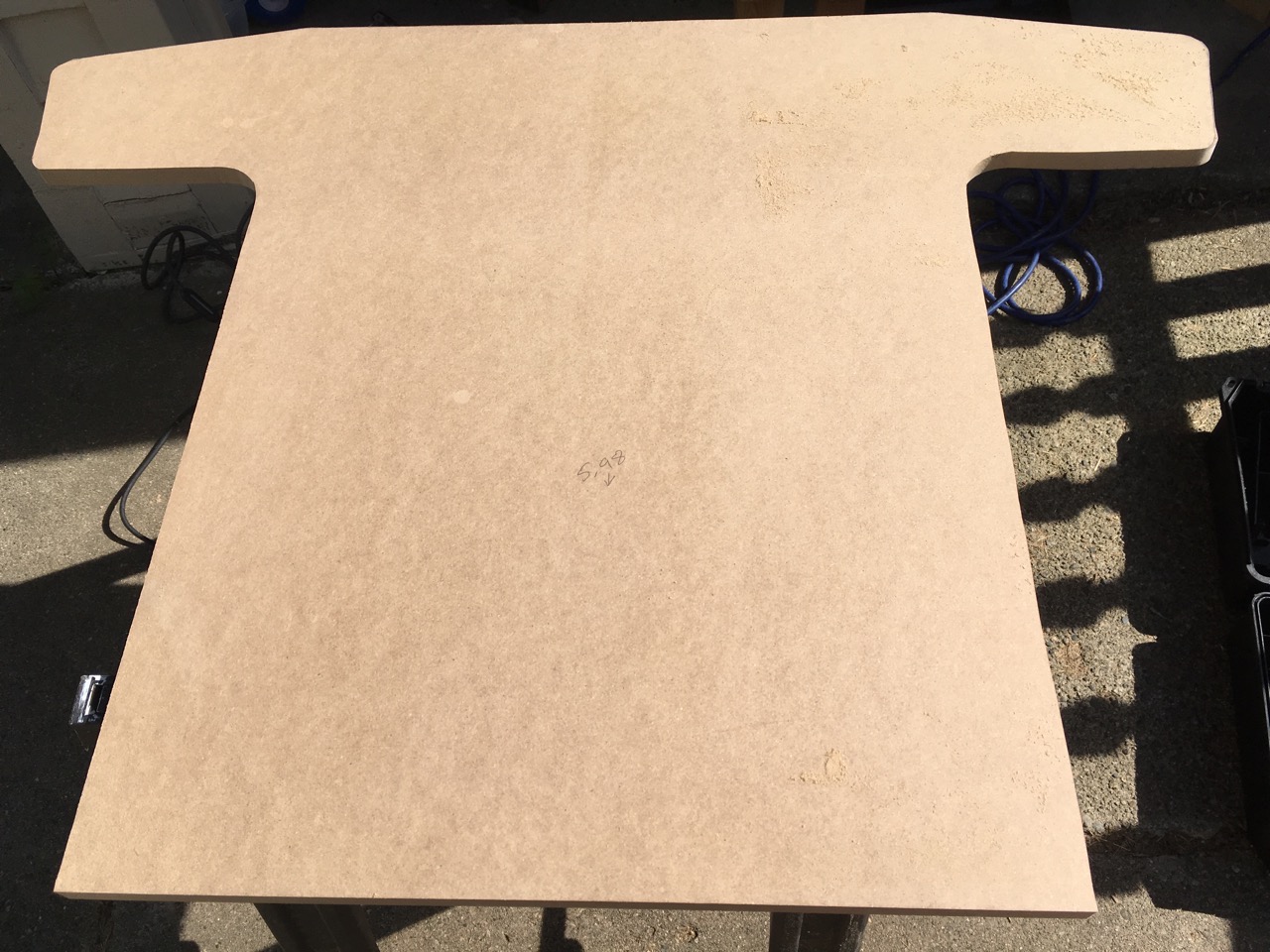

As time allows, I’ve been busing cutting out pieces for the Track & Field cocktail cabinet. Mostly, everything has been going okay.

While planning this project I decided to use 3/4” Medium Density Fiberboard (MDF) as my material. Reading around on build out forums, there’s some debate about which is the better material – MDF or plywood. Each has their merits, but I went with MDF because I think it’s more forgiving than plywood when cutting curves and sanding.

Cutting

I haven’t done much work with MDF in the past and I’m no Norm Abrams, so here’s what I’ve learned so far: making straight cuts is hard.

For my first side piece, I tried cutting the entire thing with my jigsaw using some Bosch T380B blades. Mistake. Cutting slowly wasn’t good enough, especially around the curves where the control panel curves out. There were some waves when I got done, but I was able to get most of them out with my random orbit sander. What’s left isn’t perfect, but I don’t think it will be noticeable once the t-molding is on.

The second side was cut mostly with my circular saw which went much better. I cut as many straight lines with that as I could reserving the corner curves for my jigsaw.

The circular saw is better at cutting straight lines, but it’s still rather easy to drift off guide line and make a bad angle. So smaller pieces like the kick plate beneath the access door and the bottom were done on my table saw.

Clamping down a straight edge (like a 2’ x 4’), when using the jigsaw or circular saw is immensely helpful.

Fastening & Gluing

I want my cabinet to be durable. The finished cabinet will probably be heavy and it should be able to survive moving. I think it’ll be fun to lug along to parties and maybe even to throw it in the break at work to let my coworkers battle out some high scores.

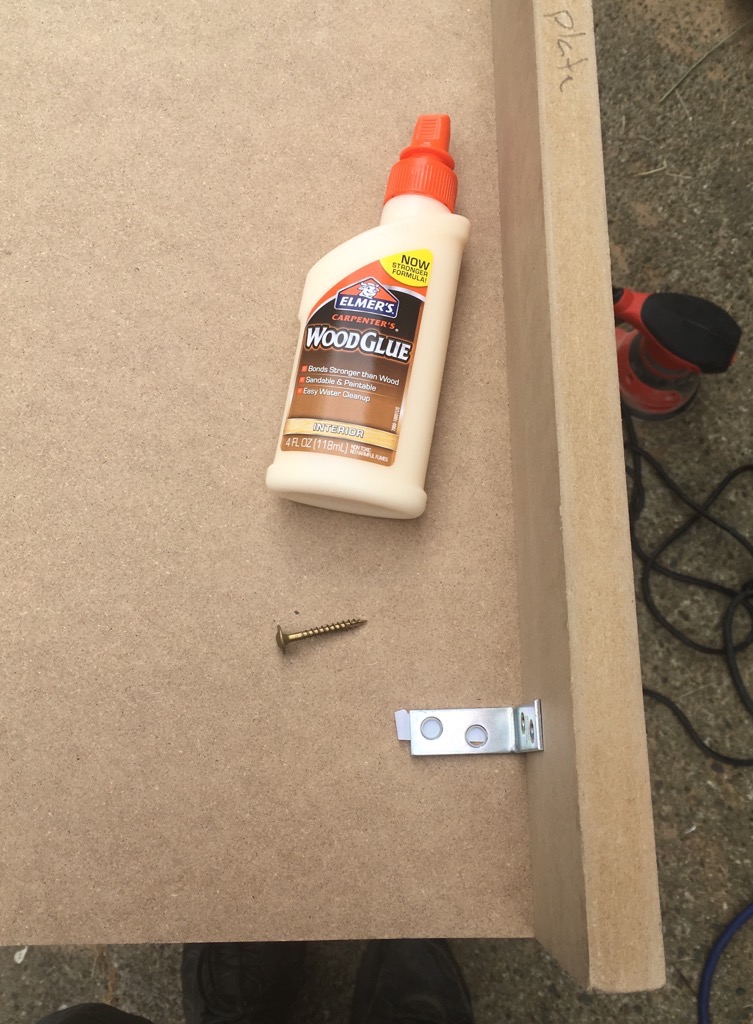

In Scr33n’s video, you can see that he used L-shaped corner braces to connect his MDF pieces together. I’m also using L braces, but I bought smaller braces than I would have liked. Larger braces were over a dollar a piece and I figure I’m going to need almost 30 of them to complete my project.

Smaller braces shouldn’t cause my any troubles because I have some 4’ clamps and I’m using wood glue to secure every joint that I can. I’m going to put some bracing pieces of wood along the critical joints, and I bought a box of cabinet screws for additional strength. It’d be nice if I had a biscuit joiner, but I’m forcing myself to live without one for now.

In this picture you can see that I drilled out space for the head of the cabinet screw.

In this picture you can see that I drilled out space for the head of the cabinet screw.

Here you can see the countersunk screw. I didn’t make quite a deep enough hole, but that’s okay because this is on the bottom of the cabinet where no one will ever see.

Here you can see the countersunk screw. I didn’t make quite a deep enough hole, but that’s okay because this is on the bottom of the cabinet where no one will ever see.

Comments

classicarcadeprojects